- Home Page

- Company Profile

-

Our Products

- Electric Transformers

- Dry Type Transformers

- Control Transformers

- Cast Resin Transformers

- Ul Approved Transformers

- Resin Encapsulated Transformer

- Industrial Control Transformer

- Step UP Down Transformer

- Single Phase Auto Transformer

- Electrical Voltage Transformer

- Ultra Isolation Transformers

- High Frequency Transformers

- Electrical Inverter Transformers

- Step Up Transformer

- Step down transformer

- Single Phase Transformer

- Electrical AC Transformer

- Electronic Avionic Transformers

- Electrical Power Transformer

- Low Voltage Transformers

- Electrical Switching Transformer

- Ultra Isolation Transformers

- Current Transformers

- Electrical Ignition Transformers

- Variable Auto Transformer

- Constant Voltage Transformer

- Single Phase Pulse Transformer

- Electrical Ferrite Transformer

- Electrical Special Transformer

- Inductors & Panels

- Control panel

- Load Reactors

- Isolation transformers

- Detuned Reactors

- CE & UL marked Transformers

- Dry Type Lighting Transformer for Electrical Ap

- Power Transformers

- Control Transformers

- Sinusoidal Filters

- Magnetic Transformers

- Lighting Transformers

- High Frequency Inductors

- DC Electronic Chokes

- Cast Resin Transformers

- Unitized Substation

- Electronic Choke

- Furnace Transformer

- Electric Transformers

- Contact Us

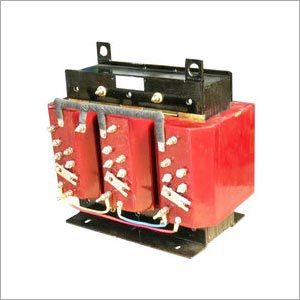

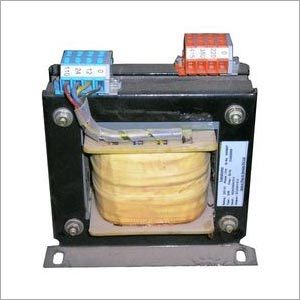

Control Transformers

Price 10000.00 INR/ Unit

MOQ : 1 Unit

Control Transformers Specification

- Cooling Type

- Air Cooled (Dry Type)

- Rated Voltage

- Up to 1000V

- Load Loss

- Low (as per IS standards)

- Dimension (L*W*H)

- Custom, as per rating and type

- High Voltage

- 230V / 415V AC

- Coil Material

- Electrolytic Copper

- Low Voltage

- 12V / 24V / 110V / 230V AC

- Capacity

- 0.5 kVA to 100 kVA

- Voltage Booster Type

- Step Down / Step Up

- Product Type

- Control Transformer

- Output

- 12V / 24V / 110V / 230V (as per requirement)

- Frequency (MHz)

- 50 Hz / 60 Hz

- Efficiency

- Up to 98%

- Phase

- Single Phase / Three Phase

- Usage

- Industrial, Control Panel, Automation Systems

- Coil Structure

- Toroidal / Layer Wound

- Coil Number

- Double Wound

- Power Scope

- Up to 100 kVA

Control Transformers Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Certifications

- An ISO 9001:2008, ISO 2001:2000 & ISO 9001:2000 certified company

About Control Transformers

Since our inception in 1985, we are counted amongst as the leading manufacturer, exporter and supplier of Control Transformers. The provided transformers are air cooled transformers that controls the voltage at output side. Owing to their unmatched property these transformers are widely demanded in various industries and other commercial and residential sectors. Manufactured as per set international standards using optimal quality basic components, the offered transformers are also tested by our adroit quality controllers. We are offering these Control Transformers in different technical specifications to meet the diverse need of our clients.

Features of Control Transformers:

- Robust construction

- Durable finish

- User friendly design

- Noise-free operations

Product details ofControl Transformers:

|

Enclosure Type |

Enclosure / without enclosure (IP00) |

|

Insulation |

Class F or Class H |

|

Type |

1-phase, 3-phase |

|

Frequency |

50/ 60 Hz |

|

Power |

100VA to 40KVA |

FAQs ofControl Transformers:

Q1: What is a control transformer?

A1: A control transformer is an electrical gadget intended to step down voltage levels for use in fueling control circuits in different modern and business applications.

Q2: Why are control transformers important?

A2: Control transformers are fundamental in light of the fact that many control gadgets, similar to transfers and clocks, require a lower voltage than what is ordinarily accessible in the primary power supply. Control transformers step down the voltage to a more secure and more reasonable level for these gadgets.

Q3: What are the normal voltage appraisals for control transformers?

A3: Control transformers commonly have an essential voltage rating of 120V or 240V and an optional voltage rating of 24V, 12V, or other reasonable control voltage levels.

Q4: How does a control transformer work?

A4: Control transformers work through electromagnetic enlistment. At the point when voltage is applied to the essential winding, it makes an attractive field. This attractive field prompts a voltage in the optional twisting at a lower voltage level because of the distinction in the quantity of windings.

Q5: What is the reason for the essential and optional windings in a control transformer?

A5: The essential winding is associated with the principal power supply and gets the higher voltage. The auxiliary winding is associated with the control circuit and gives the lower voltage expected to control gadgets.

Q6: What is the contrast between a control transformer and a power transformer?

A6: Control transformers are intended to give a steady, lower voltage for control circuits, while power transformers are utilized to move forward or step down voltage levels for the transmission and conveyance of electrical power.

Engineered for Versatility and Performance

These control transformers are suitable for a wide range of industrial settings, including control panels and highly automated systems. Designed to handle single-phase or three-phase power, they can be customized to deliver various output voltages and capacities, ensuring seamless integration into diverse operational environments.

Custom Solutions for Varied Applications

From 0.5 kVA up to 100 kVA, our transformers can be tailored in size and voltage specification to meet specific project parameters. With options in coil structure and material, along with both step-up and step-down capabilities, they offer reliable performance for your unique electrical needs.

High Efficiency, Low Loss Design

Achieve optimal energy utilization with an efficiency of up to 98%. The transformers are air-cooled (dry type) and exhibit low load loss as per IS standards, making them both cost-effective and energy efficient for long-term operation.

FAQs of Control Transformers:

Q: How do control transformers enhance the safety and efficiency of industrial automation systems?

A: Control transformers provide consistent and reliable output voltage to sensitive control circuits, protecting devices and ensuring stable operation. Their high efficiency and low load losses contribute to energy savings and reduce the likelihood of voltage fluctuations that could disrupt automated processes.Q: What is the process for selecting the right transformer configuration for my control panel or automation application?

A: Start by evaluating your equipments voltage and phase requirements, power capacity (up to 100 kVA), and frequency (50/60 Hz). Choose output voltages (12V, 24V, 110V, or 230V) and coil structures (toroidal or layer wound) that match your systems needs. Our team can help customize the transformers dimensions and configurations for optimal integration.Q: When is it advisable to use a step-up versus a step-down control transformer?

A: A step-down transformer is used when the supplied voltage is higher than the required voltage for your equipment or control circuits, while a step-up transformer increases the voltage to meet equipment demands when the input supply is lower than needed.Q: Where are these control transformers most commonly installed?

A: These transformers are widely used in various industrial sectors, automation systems, and integrated within control panels. Due to their robust design and customizable nature, they are ideal for factories, process plants, machinery control circuits, and automation equipment setups.Q: What are the benefits of choosing electrolytic copper for the coil material?

A: Electrolytic copper offers superior conductivity, leading to higher efficiency and lower energy losses. This material ensures robust performance, reduced heat generation, and enhances the longevity of the transformer, making it a reliable choice for intensive industrial use.Q: How does the cooling type impact transformer operation and maintenance?

A: Our transformers use air cooling (dry type), which eliminates the risk of oil leaks, reduces maintenance needs, and provides safer operation in indoor and panel-mounted applications. The design ensures effective heat dissipation, maintaining performance even during continuous operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electric Transformers Category

Electrical Voltage Transformer

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Phase : Three Phase

Frequency (MHz) : 50/60 Hz

Usage : Voltage regulation and electrical power transmission

Rated Voltage : 11 kV / 0.415 kV

Current Transformers

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Phase : Three Phase

Frequency (MHz) : 50/60 Hz

Usage : Current measurement in electrical systems

Rated Voltage : Up to 33 kV

Electrical Ferrite Transformer

Minimum Order Quantity : 1 Piece

Phase : Other, Single / Three Phase

Frequency (MHz) : 20 500 KHz Hertz (HZ)

Usage : Industrial

Rated Voltage : 220 Volts Volt (V)

Cast Resin Transformers

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Phase : Three Phase

Frequency (MHz) : 50 Hz

Usage : Industrial Power Distribution and Electrical Systems

Rated Voltage : 11 kV / 0.433 kV

Send Inquiry

Send Inquiry