- Home Page

- Company Profile

-

Our Products

- Electric Transformers

- Dry Type Transformers

- Control Transformers

- Cast Resin Dry Type Transformers

- Ul Approved Transformers

- Resin Encapsulated Transformer

- Industrial Control Transformer

- Step UP Down Transformer

- Single Phase Auto Transformer

- Electrical Voltage Transformer

- Three Phase Ultra Isolation Transformers

- High Frequency Transformers

- Electrical Inverter Transformers

- Step Up Transformer

- Step down transformer

- Single Phase Transformer

- Electrical AC Transformer

- Electronic Avionic Transformers

- Electrical Power Transformer

- Low Voltage Transformers

- Electrical Switching Transformer

- Ultra Isolation Transformers

- Current Transformers

- Electrical Ignition Transformers

- Variable Auto Transformer

- Constant Voltage Transformer

- Single Phase Pulse Transformer

- Electrical Ferrite Transformer

- Electrical Special Transformer

- Inductors & Panels

- Control panel

- Load Reactors

- Isolation transformers

- Detuned Reactors

- CE & UL marked Transformers

- Dry Type Lighting Transformer for Electrical Ap

- Power Transformers

- Control Transformers

- Sinusoidal Filters

- Magnetic Transformers

- Lighting Transformers

- High Frequency Inductors

- DC Electronic Chokes

- Cast Resin Transformers

- Unitized Substation

- Electronic Choke

- Furnace Transformer

- Electric Transformers

- Contact Us

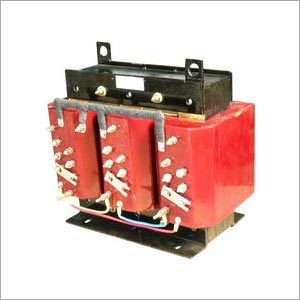

Cast Resin Dry Type Transformers

Price 10000.00 INR/ Unit

MOQ : 1 Unit

Cast Resin Dry Type Transformers Specification

- Coil Material

- Copper / Aluminium

- Load Loss

- As per IS:1180 and IEC 60726 Standards

- Low Voltage

- 415 V / 433 V Volt (V)

- High Voltage

- Up to 36 kV Volt (V)

- Rated Voltage

- 11 kV / 0.433 kV Volt (V)

- Product Type

- Cast Resin Transformer

- Output

- Customized as per Requirement

- Frequency (MHz)

- 50 Hz Hertz (HZ)

- Efficiency

- Up to 98%

- Phase

- Three Phase

- Usage

- Industrial Power Distribution and Electrical Systems

- Coil Structure

- Toroidal / Layered Coils

- Coil Number

- Double Wound

- Power Scope

- Up to 3150 kVA

- Weight

- Approx. 3000 kg (depending on rating) Kilograms (kg)

Cast Resin Dry Type Transformers Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Middle East, Eastern Europe, South America, Africa, Western Europe, Central America, Australia, Asia, North America

- Certifications

- An ISO 9001:2008, ISO 2001:2000 & ISO 9001:2000 certified company

About Cast Resin Dry Type Transformers

By keeping track with current market trend, we manufacture, export and supply high quality Cast Resin Transformers. The offered products are manufactured by our trained professionals using optimal quality components and cutting-edge methodologies. These transformers are suitable for heavy industrial applications. Due to their compact size, these transformers are widely appreciated amongst clients. The provided transformers are manufactured by our skilled professionals using optimum quality components and cutting-edge technologies. Further, these Cast Resin Transformers are available in various technical specifications according to the diverse requirement of clients.

Features of Cast Resin Transformers:

- Durable finish

- Optimal performance

- Energy efficient

- Reliable operation

Product details ofCast Resin Transformers:

|

Ambient Temperature |

plus/minus 60 Degree C |

|

Application |

Distribution Transformers, Power Transformers, Transformers for static converters |

|

Phase |

Three Phase |

|

Cooling Type |

Cast resin |

|

Output Voltage |

Up to 11 Kv |

|

Power (VA) |

1000 Kva |

FAQs ofCast Resin Transformers:

Q: What is a cast resin transformer?

A: A cast resin transformer, otherwise called a dry-type cast resin transformer, is a sort of electrical transformer that utilizations epoxy resin as both the protection material and the cooling medium. It is intended to be harmless to the ecosystem and is appropriate for different indoor and open air applications.

Q: How in all actuality do cast resin transformers cool themselves?

A: Cast resin transformers depend on normal convection and radiation for cooling. The epoxy resin embodying the windings disperses heat produced during activity. Some bigger cast resin transformers may likewise incorporate cooling fans or extra cooling courses of action for upgraded heat dispersal.

Q: Are cast resin transformers more costly than oil-filled transformers?

A: Cast resin transformers will generally be more costly than oil-filled transformers of comparative appraisals. Notwithstanding, the all out cost of possession might be lower because of decreased support necessities and ecological advantages.

Q: Can cast resin transformers be altered for explicit applications?

A: Indeed, makers frequently give choices to modifying cast resin transformers to meet explicit voltage, power, and natural necessities. These customizations can incorporate size, voltage appraisals, and protection frameworks custom-made to the application.

Q: How are cast resin transformers appraised or determined?

A: Cast resin transformers are determined in light of different boundaries, including their power rating (in kVA), essential and auxiliary voltage appraisals, protection class, and different elements like the quantity of stages and cooling strategy.

Q: Are cast resin transformers appropriate for use in cruel conditions?

A: Indeed, cast resin transformers are intended to endure brutal ecological circumstances, including high moistness, substance openness, and temperature limits. They are much of the time utilized in requesting open air applications, for example, wind ranches and modern establishments.

Q: Do cast resin transformers require customary support?

A: Cast resin transformers by and large require less support contrasted with oil-filled transformers. Nonetheless, routine investigations and checks for indications of overheating, defilement, or harm are as yet prescribed to guarantee their drawn out unwavering quality.

Q: Are there explicit security contemplations while introducing and working cast resin transformers?

A: Indeed, security contemplations incorporate legitimate establishing, satisfactory ventilation, and consistence with nearby electrical codes and guidelines. Following the maker establishment and support rules for safe operation is fundamental.

Customized Transformer Solutions for Industrial Needs

These cast resin transformers are tailored to meet the diverse requirements of various industries. Available in capacities from 100 kVA to 3150 kVA and supporting both toroidal and layered coil designs, our transformers excel in environments where reliability and efficiency are key. Every unit can be configured to client-specific output parameters, ensuring seamless integration into any power distribution system.

High Performance and Safety Standards

Constructed using copper, aluminium, or specialized materials, our transformers maintain load losses compliant with IS:1180 and IEC 60726. With a high operational efficiency of up to 98% and robust three-phase performance, these transformers provide reliable service with minimal maintenance. Their sealed cast resin construction also offers enhanced protection against harsh industrial conditions.

FAQs of Cast Resin Transformers:

Q: How are cast resin transformers used in industrial power distribution systems?

A: Cast resin transformers serve as critical components in industrial power distribution by efficiently stepping down high voltages (up to 36 kV) to usable levels (415/433 V) for various machinery and processes, ensuring reliable and safe electrical power across manufacturing facilities.Q: What benefits do cast resin transformers offer over traditional oil-immersed transformers?

A: Unlike oil-immersed types, cast resin transformers are safer and more environmentally friendly, offering excellent fire resistance and lower risk of leakage. Their cast resin insulation also reduces maintenance requirements, making them well-suited for indoor and industrial environments.Q: When is it recommended to use a cast resin transformer in an electrical system?

A: A cast resin transformer is ideal when your application demands high reliability, enhanced safety, and minimal maintenanceespecially in locations with stringent fire safety requirements or limited ventilation, such as industrial plants and urban installations.Q: Where are these transformers manufactured and supplied from?

A: These cast resin transformers are manufactured, exported, and supplied from India. As an established exporter, manufacturer, and supplier, we deliver standard-compliant, customized solutions to clients across the country and globally.Q: What is the typical process for customizing a cast resin transformer to meet specific requirements?

A: Customization involves reviewing the clients voltage, capacity, and application needs. Technical parameterssuch as power scope, coil material, dimensions, and connection configurationare tailored during design and manufacturing, ensuring every transformer fits the intended electrical system precisely.Q: How does the efficiency and design of the coil structure impact transformer performance?

A: With efficiencies reaching up to 98%, the choice of toroidal or layered, double-wound coilscrafted from copper, aluminium, or other materialsensures optimal electrical performance, reduced load losses, and adherence to IS:1180 and IEC 60726 standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electric Transformers Category

Industrial Control Transformer

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Output : 12V / 24V / 48V (as per requirement)

Product Type : Other, Industrial Control Transformer

Rated Voltage : 220V / 230V / 240V

Usage : Industrial Automation

Electrical Voltage Transformer

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Output : Customized as per requirements

Product Type : Other, Electrical Voltage Transformer

Rated Voltage : 11 kV / 0.415 kV

Usage : Voltage regulation and electrical power transmission

Electrical Special Transformer

Minimum Order Quantity : 1 Piece

Output : 5 MVA

Product Type : Other, Electrical Special Transformer

Rated Voltage : 11 kV

Usage : Industrial

Ul Approved Transformers

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Output : Variable based on model

Product Type : Other, UL Approved Transformer

Rated Voltage : 230V / 415V

Usage : Industrial, Electrical and Electronic Equipment

Send Inquiry

Send Inquiry