- Home Page

- Company Profile

-

Our Products

- Electric Transformers

- Dry Type Transformers

- Control Transformers

- Cast Resin Transformers

- Ul Approved Transformers

- Resin Encapsulated Transformer

- Industrial Control Transformer

- Step UP Down Transformer

- Single Phase Auto Transformer

- Electrical Voltage Transformer

- Ultra Isolation Transformers

- High Frequency Transformers

- Electrical Inverter Transformers

- Step Up Transformer

- Step down transformer

- Single Phase Transformer

- Electrical AC Transformer

- Electronic Avionic Transformers

- Electrical Power Transformer

- Low Voltage Transformers

- Electrical Switching Transformer

- Ultra Isolation Transformers

- Current Transformers

- Electrical Ignition Transformers

- Variable Auto Transformer

- Constant Voltage Transformer

- Single Phase Pulse Transformer

- Electrical Ferrite Transformer

- Electrical Special Transformer

- Inductors & Panels

- Control panel

- Load Reactors

- Isolation transformers

- Detuned Reactors

- CE & UL marked Transformers

- Electric Moters

- Dry Type Lighting Transformer for Electrical Ap

- Power Transformers

- Control Transformers

- Sinusoidal Filters

- Magnetic Transformers

- Distribution Transformer

- Lighting Transformers

- High Frequency Inductors

- Power Switchgears

- Phoenix Terminal Blocks

- DC Electronic Chokes

- Cast Resin Transformers

- Unitized Substation

- Substation Transformer

- Electronic Choke

- Furnace Transformer

- Voltage stabilizers

- Electric Transformers

- Contact Us

Dry Type Transformers

Price 10000.00 INR/ Unit

MOQ : 1 Unit

Dry Type Transformers Specification

- High Voltage

- Up to 33,000 V

- Voltage Booster Type

- Step Down / Step Up

- Low Voltage

- 415 V / 433 V (Standard LV)

- Coil Material

- Copper or Aluminum

- Capacity

- Varies (commonly 100 kVA 2500 kVA)

- Rated Voltage

- Up to 33 kV

- Dimension (L*W*H)

- As per design (typically 1200 x 900 x 1400 mm and above)

- Load Loss

- Low (in compliance with IS 11171/IEC standards)

- Product Type

- Dry Type Transformer

- Material

- Copper / Aluminum

- Output

- Customized as per requirement

- Frequency (MHz)

- 50 Hz

- Efficiency

- Up to 99%

- Phase

- Three Phase

- Usage

- Industrial / Electrical Equipment / Distribution

- Coil Structure

- Toroidal / Layer Wound

- Coil Number

- Two or more (depending on configuration)

- Power Scope

- Up to 2500 kVA

- Weight

- As per rating (approx. 500 kg 3000 kg)

Dry Type Transformers Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Customized packing.

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2008, ISO 2001:2000 & ISO 9001:2000 certified company

About Dry Type Transformers

As an ISO 9001:2008 certified company, we hold expertise in offering a premium quality range of Dry Type Transformers that are suitable for installation in malls, home, offices and other indoor areas. These transformers consist of insulation class that provides specified voltage. The provided transformers are manufactured using optimum quality components and modern methodologies. Our clients can avail these Dry Type Transformers in various specifications from us at market leading prices.

Dry-Type transformers have advances over oil-immersed transformers. An important issue is safety. With minimum maintenance and long life, they have no fire hazard and do not need any venting to toxic gases. These do not have any ecological restrictions and are convenient because of their compact sizes. GPDL specializes in dry-type transformers since more than 30 years.

Key Specification of Dry Type Transformers:-

- Power Rating Up to 1000 KV

- Nominal Voltage Up to 11

- Air Cooled / Force Cooled

- Insulation Up to Class H

- 4% Impedance unless specification

- Enclosure Ingress Protection Up to 55

- Customized Solution for all Dry Type Transformer

- Varnish (Resin)

Features of Dry Type Transformers:

- Optimum performance

- High load bearing capacity

- Easy to operate

-

Reliable operation

Product details ofDry Type Transformers:

|

Ambient Temperature |

-40 to + 40 Degree C |

|

Coil Structure |

Toroidal |

|

Insulation Level |

H |

|

Primary Voltage |

Up to 11 kV |

|

Phase |

Three Phase |

|

Power/Capacity |

Up to 1 MVA |

FAQs ofDry Type Transformers:

Q: What is a dry-type transformer?

A: A dry-type transformer is an electrical transformer that utilizations air or strong protection to cool and protect its windings, instead of a fluid filled transformer, which utilizations oil or other dielectric liquids for protection and cooling.

Q: Where are dry-type transformers usually utilized?

A: Dry-type transformers are normally utilized in different applications, including business and modern structures, medical clinics, schools, server farms, and other indoor areas. They are additionally liked in circumstances where fire wellbeing and ecological worries are significant.

Q: Can dry-type transformers be tweaked for explicit applications?

A: Indeed, dry-type transformers can be tweaked to meet explicit voltage, power, and ecological necessities. Makers offer a scope of standard and specially crafts to suit various applications.

Q: Are dry-type transformers more costly than oil-filled transformers?

A: Dry-type transformers will generally be more costly than oil-filled transformers of comparative appraisals. Notwithstanding, the complete expense of possession might be lower because of diminished support, lower fire dangers, and ecological advantages.

Q: What are the regular effectiveness levels of dry-type transformers?

A: The proficiency of dry-type transformers shifts relying upon their plan and size. Current dry-type transformers are intended to meet or surpass energy proficiency principles, for example, those predetermined by associations like NEMA (Public Electrical Makers Affiliation) or DOE (U.S. Division of Energy).

Versatile and Reliable Design

Our Dry Type Transformers are engineered to support a wide range of industrial and distribution applications. With copper or aluminum windings and sophisticated coil structures, they are built for durability, safety, and consistent performance in demanding environments. The transformers are available in both toroidal and layer wound variants to suit specific installation requirements.

Customization for Diverse Needs

Every system is different, which is why our dry type transformers can be tailored for output, size, and voltageup to 33,000 V on the high voltage side or 415 V/433 V low voltage outputs. This adaptability makes them ideal for unique industrial setups, ensuring optimal integration with your existing electrical infrastructure.

Export Quality from India

Manufactured to global standards with rigorous quality controls, our transformers serve clients worldwide. With low load loss and compliant with IS 11171/IEC, you can expect energy efficiency and a long operational life, making them a sound investment for your power needs.

FAQs of Dry Type Transformers:

Q: How are dry type transformers utilized in industrial and distribution applications?

A: Dry type transformers are primarily used to distribute electrical power safely and efficiently in industrial facilities and commercial buildings. Their robust construction and high efficiency make them suitable for continuous operation in demanding environments, supplying reliable power to critical equipment and electrical networks.Q: What materials are used in the coil structure of these transformers?

A: Our transformers utilize coils made from copper, aluminum, or a suitable alternative, configured in either toroidal or layer wound structures. The material selection depends on the required performance, efficiency, and cost considerations specific to the customers application.Q: When should I opt for a step-up or step-down voltage booster transformer?

A: A step-up transformer is needed when increasing voltage for transmission over long distances is required, while a step-down transformer is used to reduce voltage levels for end-user equipment or distribution systems. The choice depends on your specific operational requirements and distribution network design.Q: Where can these dry type transformers be installed?

A: These transformers are designed for indoor installations in industrial plants, warehouses, and commercial facilities, where dry-type solutions are preferred for safety and ease of maintenance. Customizations in size and design allow them to fit into varied spatial constraints.Q: What is the manufacturing process for dry type transformers?

A: The process involves precise design, selection of core materials, coil winding (copper/aluminum), insulation application, and assembly as per IS 11171/IEC standards. Each transformer undergoes rigorous testing for efficiency, safety, and reliability before delivery to the customer.Q: How does using a dry type transformer benefit my facility?

A: Adopting a dry type transformer enhances operational safety, improves energy efficiency (up to 99%), and reduces maintenance needs compared to oil-filled alternatives. Their compliance with stringent standards ensures durability and reliable power distribution over long service life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electric Transformers Category

Current Transformers

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency (MHz) : 50/60 Hz

Phase : Three Phase

Usage : Current measurement in electrical systems

Cooling Type : Aircooled (Dry type)

Variable Auto Transformer

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency (MHz) : 50/60 Hz

Phase : Other, Single or Three Phase

Usage : Voltage regulation, laboratory testing, industrial control

Cooling Type : Air cooled

Electrical Inverter Transformers

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hertz (HZ)

Phase : Single Phase

Usage : Industrial

Cooling Type : Air Cooled

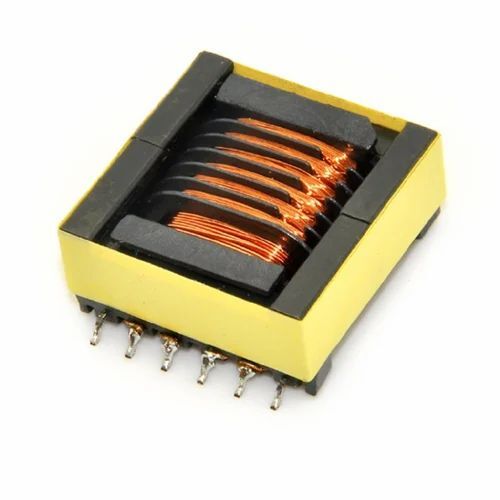

High Frequency Transformers

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hertz (HZ)

Phase : Single Phase

Usage : Industrial

Cooling Type : Air Cooled

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free