- Home Page

- Company Profile

-

Our Products

- Electric Transformers

- Dry Type Transformers

- Control Transformers

- Cast Resin Transformers

- Ul Approved Transformers

- Resin Encapsulated Transformer

- Industrial Control Transformer

- Step UP Down Transformer

- Single Phase Auto Transformer

- Electrical Voltage Transformer

- Ultra Isolation Transformers

- High Frequency Transformers

- Electrical Inverter Transformers

- Step Up Transformer

- Step down transformer

- Single Phase Transformer

- Electrical AC Transformer

- Electronic Avionic Transformers

- Electrical Power Transformer

- Low Voltage Transformers

- Electrical Switching Transformer

- Ultra Isolation Transformers

- Current Transformers

- Electrical Ignition Transformers

- Variable Auto Transformer

- Constant Voltage Transformer

- Single Phase Pulse Transformer

- Electrical Ferrite Transformer

- Electrical Special Transformer

- Inductors & Panels

- Control panel

- Load Reactors

- Isolation transformers

- Detuned Reactors

- CE & UL marked Transformers

- Dry Type Lighting Transformer for Electrical Ap

- Power Transformers

- Control Transformers

- Sinusoidal Filters

- Magnetic Transformers

- Lighting Transformers

- High Frequency Inductors

- DC Electronic Chokes

- Cast Resin Transformers

- Unitized Substation

- Electronic Choke

- Furnace Transformer

- Electric Transformers

- Contact Us

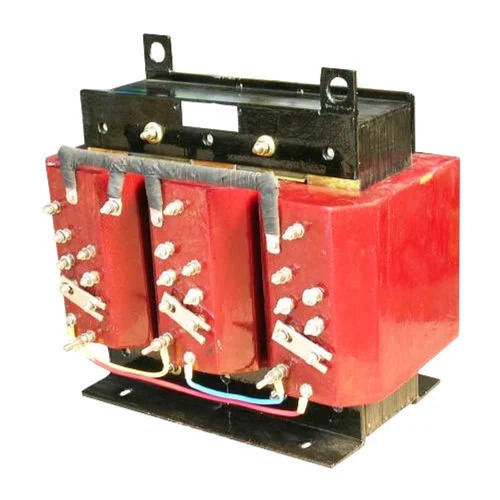

Resin Encapsulated Transformer

Price 1000.00 INR/ Unit

MOQ : 1 Unit

Resin Encapsulated Transformer Specification

- Cooling Type

- AN / AF (Air Natural / Air Forced)

- High Voltage

- Up to 36 kV

- Operating Temperature

- -25C to +50C

- Voltage Booster Type

- Step-up / Step-down

- Standard

- IS 11171, IEC 60076

- Dimension (L*W*H)

- As per design and rating, customizable

- Load Loss

- As per IS/IEC standards

- Rated Voltage

- Up to 36 kV

- Capacity

- As per requirement / Standard range

- Low Voltage

- 415 V / 690 V (as specified)

- Coil Material

- Copper or Aluminum

- Product Type

- Dry Type Resin Encapsulated Transformer

- Material

- Copper/Aluminum Core with Epoxy Resin Encapsulation

- Output

- Customizable based on requirement

- Frequency (MHz)

- 50/60 Hz

- Efficiency

- Above 98%

- Phase

- Three Phase

- Usage

- Industrial, Power Distribution, Substation, Commercial Buildings

- Coil Structure

- Toroidal / Layer Wound

- Coil Number

- Primary and Secondary Windings

- Power Scope

- 100 kVA to 2500 kVA

- Weight

- 350 kg - 2500 kg (varies with rating)

Resin Encapsulated Transformer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Customized packing.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2008, ISO 2001:2000 & ISO 9001:2000 certified company

About Resin Encapsulated Transformer

High quality resin encapsulated transformer is offered by us that is in which one or more of the transformers components are completely sealed. One example of a component is the transformers coils. This process of encapsulation protects the transformer from dirt, dust, moisture, and any other contaminants. It is covered in a thicker coating of insulation than typical. Often the coils are completely encased in epoxy or an epoxy and aggregate mixture. The resin encapsulated transformer is made for easy installation.

We are leading manufacturers and exporter of Cast Resin (Resin Encapsulated) Transformer. The materials used ensure high durability, strength and resistivity to conditions favouring corrosion and abrasion.

Key Specification ofResin Encapsulated Transformer:-

- Power Rating Up to 1000 KV

- Nominal Voltage Up to 11

- Resistant to Short circuit (Highly Mechanical Strength)

- Non Inflammable

- Less Maintenance

- Highly Resistance to Moisture

- High Overload Capacity

- Long Shelf Life

- No Leakage of Oil

Product details ofResin Encapsulated Transformer:

|

Ambient Temperature |

plus/minus 60 Degree C |

|

Application |

Distribution Transformers, Power Transformers, Transformers for static converters |

|

Phase |

Three Phase |

|

Cooling Type |

Cast resin |

|

Output Voltage |

Up to 11 Kv |

|

Power (VA) |

1000 Kva |

FAQs ofResin Encapsulated Transformer:

Q1: What is a resin encapsulated transformer?

A1: A resin encapsulated transformer is an electrical transformer that has its windings and center encapsulated in a strong resin material, giving security against ecological variables like dampness, residue, and vibration.

Q2: Where are resin encapsulated transformers normally utilized?

A2: Resin encapsulated transformers are generally utilized in outside applications, for example, lighting, traffic lights, and modern apparatus, as well as in unforgiving conditions where customary transformers may be presented to dampness or impurities.

Q3: What are the upsides of resin encapsulated transformers?

A3: A few benefits of resin encapsulated transformers incorporate brilliant security against ecological elements, improved sturdiness, protection from erosion, and the capacity to work in a great many temperatures.

Q4: Can resin encapsulated transformers be utilized inside too?

A4: Indeed, resin encapsulated transformers can be utilized inside, particularly in applications where security against dampness, residue, or destructive gases is fundamental. They are flexible and can be utilized in different conditions.

Q5: Are resin encapsulated transformers more costly than customary transformers?

A5: Resin encapsulated transformers can be more costly than customary transformers because of the extra materials and assembling processes engaged with typifying the unit in resin. In any case, their drawn out strength and assurance against ecological elements can legitimize the greater expense.

Reliable Short Circuit Protection

Designed to endure both thermal and dynamic stresses, the transformer ensures resilience during short circuits. This robust construction meets IEC standards, enhancing system reliability and operational safety.

Superior Fire and Moisture Resistance

The self-extinguishing epoxy resin encapsulation delivers high fire resistance, while safeguarding internal components from humidity and dust. This makes the transformer suitable for indoor installations where environmental challenges are prominent.

Flexible Applications and Customization

With power ratings from 100 kVA to 2500 kVA, a range of voltage options, and customizable coil structures, the transformer meets a broad spectrum of industrial, substation, and commercial power needs. Optional accessories and tap changer configurations further broaden its application scope.

FAQs of Resin Encapsulated Transformer:

Q: How does the resin encapsulation improve transformer performance and safety?

A: The epoxy resin encapsulation enhances safety by providing excellent resistance to fire (self-extinguishing) and moisture ingress, which protects internal components from dust and humidity. It also allows for safe indoor usage and minimizes the risk of failure due to environmental factors.Q: What are the benefits of the transformers low noise operation in commercial settings?

A: Low noise operation reduces ambient sound pollution, making the transformer especially suitable for commercial buildings, offices, and other noise-sensitive environments. This feature ensures comfortable surroundings while maintaining high power delivery performance.Q: When should you choose a transformer with an off-circuit versus an on-load tap changer?

A: An off-circuit tap changer is ideal for applications where minor voltage adjustments can be made when the transformer is de-energized. In contrast, an on-load tap changer allows for voltage regulation without interrupting the load, benefiting systems with variable supply or fluctuating power demands.Q: Where are resin encapsulated transformers most effectively installed?

A: These transformers are particularly suitable for indoor installations such as industrial plants, substations, commercial buildings, and environments with increased exposure to dust and moisture. Their IP23/IP44 enclosure options further enhance protection in challenging locations.Q: What maintenance is required for the resin encapsulated transformer?

A: Thanks to its maintenance-free design, routine servicing is minimal. The robust resin encapsulation and quality components significantly reduce the need for periodic intervention, offering reliable performance over an extended lifecycle.Q: How does the transformer handle varying voltage requirements and operational conditions?

A: The transformer can be customized for step-up or step-down voltage boosting, with adaptable connections (Dyn11, Yyn0, etc.) and power ratings. Its high efficiency, wide ambient temperature operation range (-25C to +50C), and altitude capability up to 1000 meters without derating ensure dependable performance in diverse environments.Q: What accessories are available to enhance transformer operation and monitoring?

A: Optional accessories such as temperature indicators, protective relays, and wheels can be provided. These additions assist with operational monitoring, safety, and facilitate transformer mobility during installation or relocation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electric Transformers Category

Industrial Control Transformer

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50/60 Hz

Product Type : Other, Industrial Control Transformer

Usage : Industrial Automation

Phase : Single Phase

Electrical Voltage Transformer

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50/60 Hz

Product Type : Other, Electrical Voltage Transformer

Usage : Voltage regulation and electrical power transmission

Phase : Three Phase

Ultra Isolation Transformers

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hertz (HZ)

Usage : Industrial

Phase : Three Phase

Single Phase Pulse Transformer

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency (MHz) : 20Khz to 300Khz Hertz (HZ)

Product Type : Other, Single Phase Pulse Transformer

Usage : Switchedmode power supplies, Communication equipment, cameras, Small electronics, Automotive, house

Phase : Three Phase

Send Inquiry

Send Inquiry